Top Industrial Applications for Foam-Tipped Swabs

Published by AllSwabs.com on Oct 06, 2025

When precision, durability, and lint-free performance are non-negotiable, industrial foam swabs deliver. From electronics assemblies to optical components and cleanroom workflows, foam-tipped swabs enable controlled solvent application, consistent contact pressure, and minimal particle shedding. Below, we break down where these swabs outperform alternatives—and which styles to consider for each task.

Shop by brand: Puritan • Harmony • Teknipure • Cleantex

Why Foam-Tipped Swabs for Industry?

- Lint-free & low particle: Open-cell polyurethane foam minimizes debris vs. cotton or tissue wipes.

- Controlled absorption: Even solvent pick-up and release for streak-free cleaning.

- Tip geometries for any task: Pointed, paddle, rectangular, and wrapped/ sealed styles for tight spaces or broad coverage.

- Chemical & IPA compatibility: Works with high-purity and optical-grade solvents; verify specs per product.

- ESD-safe options: Static control handles/tips for sensitive electronics.

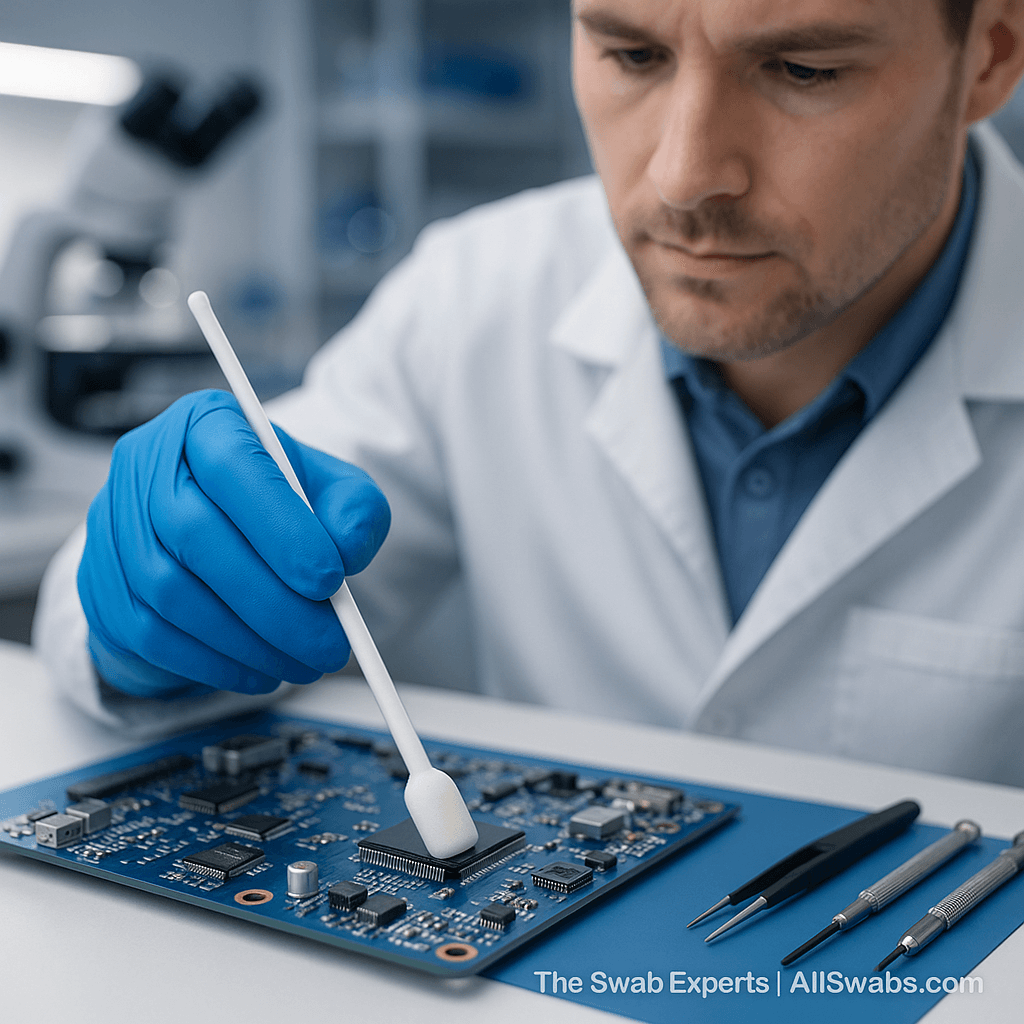

1) Electronics Assembly & Rework

Remove flux residues, oils, and particulates on solder joints, connectors, and housings. Choose paddle or rectangular tips for flat components and pointed tips for headers and pin fields. Look for ESD-safe handles where required.

2) Optics & Fiber Optic Maintenance

For ferrules, sleeves, and lenses, use wrapped or sealed foam tips to reduce scratching and fiber shedding. Apply minimal, high-purity solvent and clean in a single direction. Inspect before/after with a scope.

Start here: Fiber Optic Swabs | Brands: Teknipure, Puritan.

3) Cleanroom & Medical Device Production

Maintain ISO-compliant environments by choosing foam swabs with documented cleanliness, lot traceability, and compatible packaging. Use sealed, low-extractable tips for device interiors and component interfaces.

4) Machining, Printing & Surface Prep

Degrease edges, remove burr-trapped debris, and prep surfaces before bonding or coating. Select high-density foam for firm scrubbing and rectangular heads for fast coverage.

5) QA, Metrology & Instrument Care

Prevent cross-contamination during gauge block cleaning, lens inspection, or sensor upkeep. Use small sealed tips for delicate apertures and paddle tips for flat, high-precision surfaces.

How to Select the Right Industrial Foam Swab

- Tip geometry: Pointed for cavities; paddle/rectangular for panels; wrapped/sealed for scratch-sensitive surfaces.

- Solvent use: Confirm compatibility with IPA or optical-grade cleaners; avoid over-saturation.

- Environment: For cleanrooms, choose low-extractable, documented, and lot-tracked SKUs.

- Static sensitivity: Use ESD-safe variants around charged or static-critical assemblies.

- Handle material & length: Polypropylene for chemical resistance; select lengths to reach confined areas safely.

Ready to standardize your process with industrial foam swabs? Browse our curated category for electronics, optics, cleanrooms, and more.

Prefer shopping by brand? Puritan · Harmony · Teknipure · Cleantex