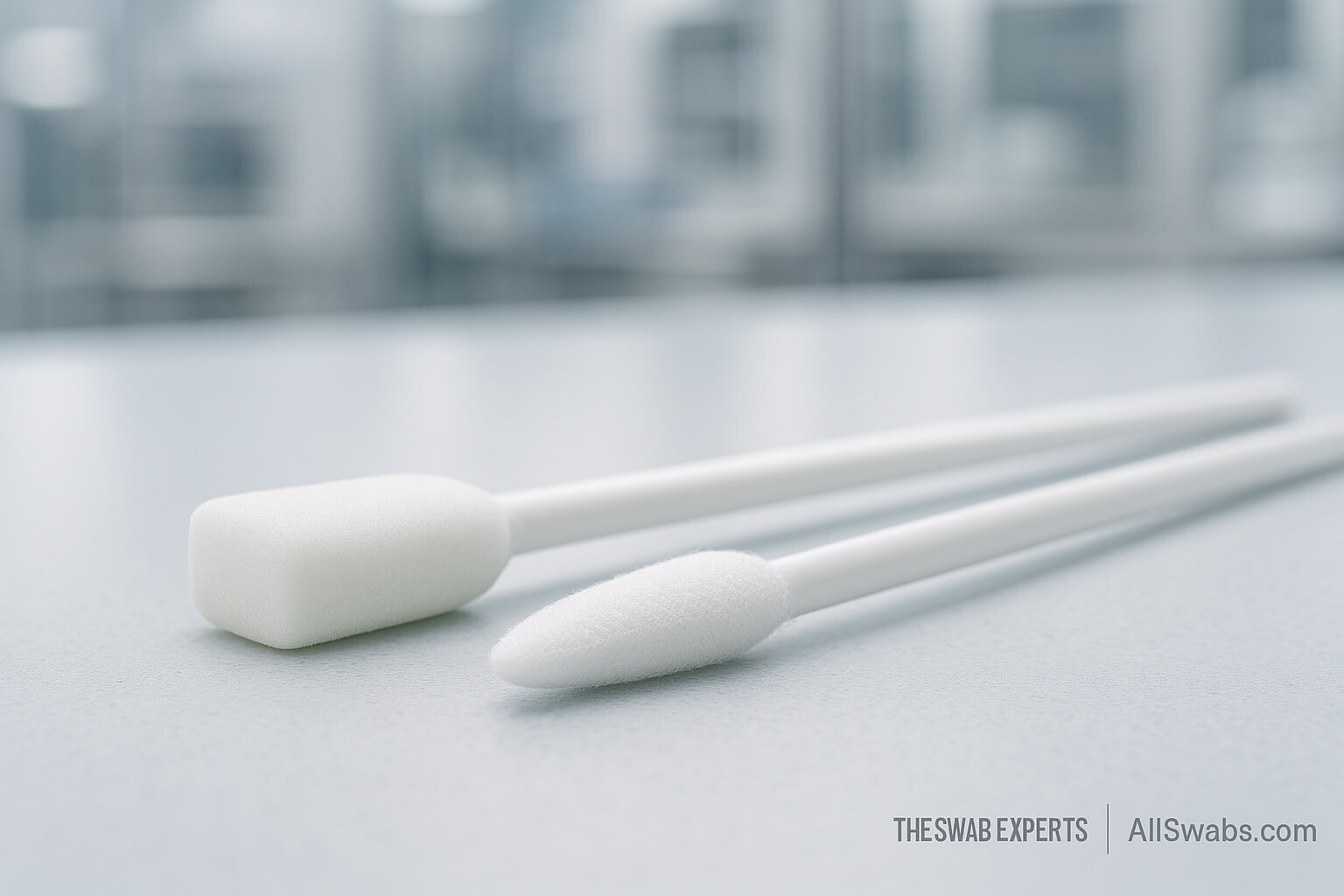

Foam vs. Polyester Swabs: Which Is Right for Your Cleanroom?

Published by AllSwabs.com on Dec 03, 2025

Foam vs. Polyester Swabs: Which Is Right for Your Cleanroom?

In a cleanroom, every tool you bring in either protects your process or puts it at risk. Swabs are a perfect example. They look simple, but the wrong tip material can shed fibers, smear residues, or react badly with solvents. When you are working in ISO Class 3–7 environments, choosing between foam and polyester swabs is more than a preference—it is a contamination control decision.

This guide breaks down the key differences between foam and polyester swabs, including absorbency, solvent compatibility, particle shedding, and cost, so you can match the right tool to your process. If you want to explore options while you read, you can browse the cleanroom-focused selections of foam swabs and polyester swabs on AllSwabs.com.

What Foam Swabs Are and When They Excel

Foam swabs are typically made from open-cell polyurethane foam bonded to a rigid or semi-rigid handle. The foam head is often sealed around the edges to keep particles contained while still allowing high absorption. This structure lets foam act like a sponge: it pulls in liquids, holds them, and releases them in a controlled way.

Technical Advantages of Foam Swabs

Foam swabs offer several strengths that make them a go-to choice in many cleanroom and production environments:

- High absorbency: Foam heads can soak up a significant amount of liquid, making them ideal for applying or removing solvents and cleaners.

- Even solvent release: The open-cell structure helps distribute liquids smoothly across a surface.

- Soft contact: The cushioned tip is gentle on sensitive surfaces and reduces the risk of scratching.

- Versatile shapes: Foam swabs are available in many head sizes and profiles, from ultra-fine tips to larger paddle heads for broader coverage.

These properties make foam swabs especially useful anywhere you need to wet, wipe, or dry surfaces quickly without leaving lint behind.

Common Cleanroom Use Cases for Foam Swabs

- Applying isopropyl alcohol or specialty cleaners to equipment housings

- Removing excess flux, lubricants, or adhesives from assemblies

- Cleaning rails, fixtures, and hard-to-reach corners inside tools

- Wiping small spills or droplets in controlled environments

For many ISO Class 6–7 cleanrooms and controlled areas, foam is a cost-effective choice that balances cleanliness with performance. You can see typical options in the foam swabs category on AllSwabs.com.

Limitations of Foam Swabs

Foam is not perfect for every application. Some limitations include:

- Not as low-shedding as high-grade knitted polyester in the most critical zones.

- Can compress under heavy pressure, which may reduce scrubbing effectiveness.

- Not always the best choice for highly aggressive solvents, depending on the foam formulation.

When processes demand the lowest possible particle and fiber counts—such as optics, wafers, or high-end electronics—polyester often becomes the preferred option.

What Polyester Swabs Are and When They Excel

Polyester swabs use a knitted or woven polyester fabric as the tip material, typically heat-sealed or laser-cut to minimize loose fibers. This construction yields a very clean, low-lint tip with excellent edge stability. The result is a swab that excels when contamination tolerance is extremely low.

Technical Advantages of Polyester Swabs

Polyester tips are engineered for critical cleaning tasks:

- Ultra-low particle shedding: Knitted polyester with sealed edges keeps fibers tightly bound.

- Excellent solvent compatibility: Polyester handles many common and aggressive solvents, including IPA and, in many cases, acetone.

- Firm, precise contact: Polyester provides a slightly firmer tip than foam, allowing controlled scrubbing and precise particle removal.

- Consistent performance: High-quality polyester swabs are manufactured with tight specifications for head size, shape, and cleanliness.

Because of these strengths, polyester swabs are frequently used in the most demanding cleanroom zones, laboratory workflows, and precision assembly environments.

Common Cleanroom Use Cases for Polyester Swabs

- Cleaning optical lenses, sensors, and glass surfaces

- Wiping critical components in ISO Class 3–5 cleanrooms

- Precision cleaning around solder joints, pads, and fine-pitch components

- Applying solvents in tightly controlled amounts to small areas

If your process cannot tolerate visible fibers or loose particles, polyester is usually the safer choice. To compare options, visit the polyester swabs category on AllSwabs.com.

Limitations of Polyester Swabs

Polyester swabs are not always the default answer:

- They are often less absorbent than foam, which may matter when you need to pick up or hold larger volumes of liquid.

- They tend to cost more per piece than standard foam swabs.

- The firmer tip may be less forgiving on very delicate soft surfaces if too much pressure is applied.

In many facilities, polyester and foam swabs are used side by side, each selected for specific tasks rather than one replacing the other completely.

Foam vs. Polyester Swabs: A Side-by-Side Comparison

When deciding between foam and polyester swabs for your cleanroom, it helps to think in terms of tradeoffs rather than winners and losers. Each material offers clear advantages depending on what you are cleaning and how strict your contamination limits are.

Absorbency

Foam swabs lead in absorbency. Their open-cell structure pulls in liquids quickly, making them ideal for wetting, soaking, and wiping. Polyester swabs can absorb liquids but are more focused on delivering controlled amounts rather than holding large volumes.

Shedding and Particle Control

Both foam and polyester cleanroom swabs are engineered to be low-lint, but polyester typically wins when particle limits are most strict. Knitted polyester with sealed edges sheds fewer fibers than foam, which is why it is often specified for ISO Class 3–5 areas and optical work.

Solvent Compatibility

Many foam swabs are designed for use with common solvents like isopropyl alcohol and mild cleaners. Polyester swabs, especially those built for cleanroom use, generally handle a wider range of solvents, including IPA and many aggressive chemistries. Always confirm compatibility with the specific swab and solvent you plan to use.

Abrasion and Cleaning Action

Foam provides a soft, cushioning contact that is gentle on surfaces. It is excellent for wiping without scratching. Polyester offers a slightly firmer feel, which can be beneficial when you need controlled scrubbing or more direct contact to remove particles or films.

Cost Considerations

Foam swabs are often more economical and are a strong choice for general-purpose cleaning in less critical cleanroom classes. Polyester swabs usually cost more but deliver added value where very low contamination and solvent compatibility are non-negotiable.

Matching Swab Type to Your ISO Cleanroom Class

Swab selection should match the cleanliness requirements of your environment.

ISO Class 3–5: Critical Zones

In these areas, every particle counts. Polyester swabs are typically recommended due to their ultra-low shedding and high solvent compatibility. They are well suited for optics, wafers, microelectronics, and other high-value components where residue and fibers must be kept to a minimum.

ISO Class 6–7: General Cleanroom Use

In less critical cleanroom zones, foam swabs are often a practical, cost-effective choice. They provide good cleanliness with higher absorbency, making them ideal for routine equipment cleaning, maintenance tasks, and broader surface work.

Facilities with Mixed Environments

Many operations contain both critical and general areas. In these cases, it usually makes sense to:

- Use polyester swabs wherever your process touches the most sensitive components or cleanest zones.

- Use foam swabs for general cleaning, solvent application, and maintenance in higher-class (numerically larger) areas.

This mixed approach keeps costs under control while aligning materials with risk levels.

Choosing the Right Swab for Specific Tasks

Another helpful way to decide is by looking at the task itself rather than the room as a whole.

Applying Solvents

Use foam swabs when you want high absorbency and broader coverage, such as wiping a housing or bracket. Choose polyester when solvent purity and compatibility are critical, or when applying small, controlled amounts to a sensitive area.

Removing Particles or Residue

For general residue removal, foam swabs work well and can hold more dissolved material. For final cleaning or precision work—especially on optics or electronics—polyester swabs provide more consistent particle removal without adding fibers.

Optical and Sensor Cleaning

Optics, sensors, and glass surfaces are unforgiving when it comes to fibers. In most cases, a high-quality polyester or microfiber swab is the recommended option, used with compatible cleaning solutions according to the manufacturer’s guidelines.

Equipment Maintenance and Fixtures

For cleaning rails, guards, fixtures, and tool exteriors in cleanrooms, foam swabs are often the most efficient choice, especially when combined with isopropyl alcohol or other approved cleaners.

Recommended Cleanroom Swab Options

AllSwabs.com focuses on swabs for industrial, cleanroom, and medical environments. If you are building or updating your cleanroom cleaning program, consider reviewing:

- Foam swabs for high-absorbency general cleaning and solvent application.

- Polyester swabs for critical cleaning where particle control is essential.

- Industrial and cleanroom swabs for a broader look at specialty tip shapes and materials.

Many facilities find that a combination of foam and polyester swabs allows them to meet both performance and budget targets. Stocking both types lets your team choose the best tool for each station and task.

Conclusion: Choose Based on Contamination Risk and Task Needs

Foam and polyester swabs both have a place in modern cleanrooms. Foam offers high absorbency, gentle contact, and strong value for general cleaning in ISO Class 6–7 areas. Polyester delivers ultra-low particle shedding, excellent solvent compatibility, and the precision needed in ISO Class 3–5 and other critical applications.

The right choice depends on what you are cleaning, which solvents you use, and how strict your contamination limits are. By aligning swab material with your cleanroom class and specific process steps, you can improve cleaning results, reduce risk, and support consistent quality across your operation.

To compare specific products, visit the cleanroom-focused collections of foam swabs and polyester swabs on AllSwabs.com, and build a swab program that fits your environment.